Shaper Cutters

Summary for Shaper Cutters

Shaper Cutters - Engineering for Smooth Profiles

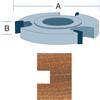

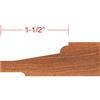

Tackle unique edge profiles, cut tongue and groove and other precision joints, and create detailed cabinet door panels with shaper cutters from our extensive selection. Choose from carbide-tipped varieties that are specially constructed for strength and durability and work with various wood varieties, composites, plywood, and some types of plastic. For professional-grade results, opt for micro-grain, carbide-tipped cutters with 5-blade, high-speed balanced cutterheads that guarantee precision for every cut.

Explore the detailed information provided in the support section of our website to learn more about shaper cutter types, selection, and safety.

Check out our special catalog that includes our available shaper cutter product line with options such as straight, profile, and stacked, and offers helpful measurements, photos, and illustrations to assist you in the selection process.

Frequently Asked Questions:

What is the difference between carbide-tipped and micro-grain carbide-tipped shaper cutters?

- Carbide-Tipped: Constructed of standard tungsten carbide tips brazed onto a steel body. They provide greater hardness and longer life than high-speed steel and create smooth cuts in hardwoods, softwoods, and laminates.

- Micro-Grain Carbide-Tipped: Made from finer carbide particles than standard carbide. Longer lasting with more wear resistance and less prone to chipping, with cleaner cuts in all material types.

What are some tips to get the most out of my shaper cutters?

- Match the spindle speed to the cutter diameter and material, using a lower speed for larger cutters and higher speed for smaller cutters.

- Maintain a steady feed rate to avoid damaging the cutter or ruining your workpiece.

- Ensure your cutters are always sharp and effective through regular inspections.

- Use push blocks and other supports to feed stock and avoid unstable and warped material.

- Use multiple shallow passes for deep cuts to achieve cleaner edges and reduce motor strain.

We are experiencing {{ network.message }}

We're sorry, we couldn't find any results{{ !keywords ? '...' : '' }}

for '{{ searchWithin }}'

{{ searchWithin ? ' within' : ' for' }}

'{{ keywords }}'

Did You Mean?

Summary for Shaper Cutters

Shaper Cutters - Engineering for Smooth Profiles

Tackle unique edge profiles, cut tongue and groove and other precision joints, and create detailed cabinet door panels with shaper cutters from our extensive selection. Choose from carbide-tipped varieties that are specially constructed for strength and durability and work with various wood varieties, composites, plywood, and some types of plastic. For professional-grade results, opt for micro-grain, carbide-tipped cutters with 5-blade, high-speed balanced cutterheads that guarantee precision for every cut.

Explore the detailed information provided in the support section of our website to learn more about shaper cutter types, selection, and safety.

Check out our special catalog that includes our available shaper cutter product line with options such as straight, profile, and stacked, and offers helpful measurements, photos, and illustrations to assist you in the selection process.

Frequently Asked Questions:

What is the difference between carbide-tipped and micro-grain carbide-tipped shaper cutters?

- Carbide-Tipped: Constructed of standard tungsten carbide tips brazed onto a steel body. They provide greater hardness and longer life than high-speed steel and create smooth cuts in hardwoods, softwoods, and laminates.

- Micro-Grain Carbide-Tipped: Made from finer carbide particles than standard carbide. Longer lasting with more wear resistance and less prone to chipping, with cleaner cuts in all material types.

What are some tips to get the most out of my shaper cutters?

- Match the spindle speed to the cutter diameter and material, using a lower speed for larger cutters and higher speed for smaller cutters.

- Maintain a steady feed rate to avoid damaging the cutter or ruining your workpiece.

- Ensure your cutters are always sharp and effective through regular inspections.

- Use push blocks and other supports to feed stock and avoid unstable and warped material.

- Use multiple shallow passes for deep cuts to achieve cleaner edges and reduce motor strain.

Shop By Category

- Abrasives & Sanding

- Adhesives

- Air Accessories

- Air Compressors

- Automotive Equipment

- Woodworking Bandsaws

- Contractor, Home & Shop

- Cutlery

- Cutting Tools

- Drill Presses

- Drilling & Boring

- Dust Collection Accessories